by Hendrik Domanovszky

engineer of transport, LNG.hu Engineering,

improved translation by Michelle Stirling

Due to the global focus on achieving “NetZero2050”, hydrogen has been elevated to the status of a kind of ‘magic bullet’ replacement for most transportation fuel and is even proposed as a replacement for natural gas for household heating uses. Nowadays Hydrogen (H2) is blithely promoted by influential persons like Mark Carney, and thus is considered a carbon-free energy vector solution, with little to no consideration that this tiniest molecule is in its artificially separated status one of the most difficult and dangerous substances to handle on earth.

The engineering community acknowledges this fact and treats hydrogen carefully, using it in the chemical industry under strict handling protocols with a respectable safety record. However, to distribute hydrogen to millions of untrained customers such as vehicle owners seems a perilous idea. Serious risks can arise due to the mass production of hydrogen fuel cells, the cost sensitivity of which might have a negative impact on material and production quality. Further risks are posed by imprudent consumer user behaviour, unqualified maintenance and repair, in which the unreliable quality of aftersales parts can increase the possibility of faults and equipment time-wear, may lead to additional, potentially catastrophic risks. Any failure within a H2-system may incur not only the cost of an unworkable vehicle, but the cost of human lives.

1. Political Focus on NetZero2050 Seeks a Carbon-free Solution for Transportation

Though battery electric vehicles (BEV) have been presented as the likely alternative to Internal Combustion Engine (ICE) fossil fuel powered transportation, it should be clear that battery technology does not present a useable solution to all transport needs. The almost 100 million vehicles manufactured globally per year cannot rely only on batteries. The Paris Agreement and various climate reports that forecast a climate crisis if greenhouse gases from fossil fuels are not reduced dramatically and in the near-term, has created political pressure to reduce CO2 emissions. This push, which was initiated more than a decade ago, focused primarily on tailpipe emission but that has not rectified the problem. Car manufacturers are now left with no better option but to sell as many locally emission-free vehicles as possible, at the cost of their business interests and partly failing to meet the expectations of their customers. This problem circle creates another civil society basis for the enthusiastic but naïve push towards Fuel Cell Electric Vehicle (FCEV) development, which is also known as “zero emission”, despite the known safety, supply, distribution and product issues related to local emission and hydrogen production.

Existing fueling and service station infrastructure easily serves ICE vehicles; BEVs are limited by a lack of suitable charging stations and limits to range which are also affected the hot or cold weather conditions. Thus, the prospect of a ‘clean’ hydrogen vehicle solution seems enticing to investors, consumers, and politicians. While some car manufacturers have developed hydrogen fuel cell vehicles, there is little refueling infrastructure, restricting that market growth. Of course, the fueling network could grow to a useful scale, if provided that: (a) the price of the hydrogen fuel allows for (b) a positive business case together with (c) the hydrogen powered vehicle penetration growth – and provided that all of this could be realized within (d) at acceptable industrial risk level within the hydrogen infrastructure network.

This downloadable study is intended to provide a knowledge basis and an overview on the problems we are facing regarding the long-term safety related to the (c) hydrogen powered vehicle penetration growth, and (d) the hydrogen infrastructure network, which together include a combination of serious hazards.

2. Consumer Vehicle Expectations Conflict with High-Risk Hazardous Hydrogen

Most consumers want to buy an affordable vehicle that will have a life use of some 20 to 40 years. Consumers are used to simple and generally safe refueling that requires little safety skill or awareness. Vehicle owners are used to easy access to repairs, most of which involve replacement of a few parts that are often available at a cheaper off-market price. Many consumers have some mechanical skills and like to tinker with their own car repairs or ‘enhancements’ to vehicle performance.

Hydrogen fuel cell vehicles challenge every one of these consumer habituations. The vehicles are less affordable, the fueling substance is extremely dangerous, the life cycle of hydrogen cells is perhaps 17 years or less, after-market/off-market parts would present serious potential quality control issues, and consumers who might feel confident in their mechanical skills on a conventional ICE vehicle might inadvertently create a potentially catastrophic scenario if they try to do their own repairs. Yet consumer behavior shows us over and over again, that most people will look for the less expensive option for repairs or upgrades. It would be difficult to create a sufficient societal level of regulation and safety standards to prevent this occurrence with hydrogen fuel cell vehicles.

The regulatory system cannot be so chaste to believe that an expensive hydrogen fuel cell system that it wants to introduce – with less than half of the lifetime needed by society today (and even more so in the future) – will result in a fleet of vehicles that remain in as safe an operational condition over their lifetime as that of a brand-new vehicle.

Hydrogen is an expensive, energy-intensive substance to produce. Safe storage and handling are even more expensive. In an industrial context, these costs can be incorporated into the facility’s construction and labor costs; at a consumer level, at all levels there will be a need to cut corners and save costs in order to make a more competitive product. This is undesirable when a sub-standard or mishandled hydrogen fuel cell vehicle’s misuse or unmonitored refueling will have catastrophic consequences for individuals, families and neighbourhoods.

Here are just some of the reasons why such an operational safety standard common to industry cannot be met:

- no tracking on the hydrogen fuel cell tanks exists, which means society cannot avoid consumer overuse of a fuel cell or vehicle past the manufacturer’s safe lifetime limits;

- no possibility of preventing consumers from doing their own repairs or maintenance on hydrogen vehicles by untrained/improperly trained personnel;

- no possibility of preventing the use of aftersales market parts, which pose risks because of the material uses and for other quality assurance reasons;

- it is not feasible to ensure stringent industrial safety levels in a low budget operational environment, particularly the developing world, and this applies to the fueling network too.

Most certainly, even a brand-new hydrogen vehicle’s safety standard is not high enough, due to the related “knowledge gaps” in quite a number of areas. Not to mention there are competitive cost reduction pressures on manufacturers associated with hydrogen technology, in every point from the fuel system through the fuel-cell system, and right down to the electric system components. These are the targets of 5-digits per vehicle cost saving measures being tried out today.

Meanwhile, H2-refilling systems have no potential to demonstrate a return on investment, though efforts to be profitable may result in sacrificing safety.

3. The Weakest Safety Link is Consumer Behavior

Until now, numerous papers have been presented on vehicle safety on the topic of hydrogen fuel cell applications for transportation, ranging from pressure equipment through crash worthiness to analysis of the behavior of the hydrogen, attempting to obtain conclusions from the different parties in the industry and scientific world. As well, there has been substantial governmental funding to support experiments. However, there have not been any studies on the behavioral reality of the potential Hydrogen Fuel Cell Vehicle (HFCV) consumers. There has been no analysis of the habits of vehicle owners, the impact of out of brand services, the risks associated with life-long usage behaviours. This means that no one really cares what will happen if hydrogen comes out of the laboratory and onto the streets of the city, or they are unaware of the serious societal risks.

4. Industrial Level Safety Standards are Not Possible in Civil Society

Hydrogen is used in industry (chemical, and not energy) level, where strict regulations, expert knowledge and strict handling protocols are in place and clear hazard identification is present. Even so, accidents happen. By contrast, the non-industrial (societal) environment is unlike the industrial one. For dozens of reasons, the risks associated with hydrogen in the non-industrial environment are not controllable and precautions are futile. As a first example, while in industrial applications each possible point of hydrogen escalation/leakage can be continuously monitored, that is not the case in consumer applications. Hydrogen is a unique molecule in that there is no odor and no color, which would allow us to recognize when a hydrogen leak is present, which presents a serious risk. Hydrogen is extremely flammable in the presence of air, or even more so, oxygen.

5. Molecular Size and Qualities

The size of the hydrogen atom is extremely small, the radius is 25 pm, or 2.5×10-11 m. Based on this small size, many of the materials presented as being ‘gas tight’, do not have sufficient molecular structure against hydrogen diffusion (escape), especially in the long term. Hydrogen is not only the lightest atom and molecule, but also the density of its gas form is very low. For this reason, hydrogen is often stored and transported in a highly compressed stage as only this way it can be used as fuel for vehicles. For cars, the targeted pressure within the hydrogen fuel cell is 700 bar, which can be exceeded by a significant amount. The compression rate causes high physical stress for the materials used to make the fuel cell container. Overtime, weaknesses in the fuel cell structure can appear; likewise, hydrogen interaction with some metals and materials makes them very brittle over time, leading to a high risk of a fissure and leakage.

6. Flammability

The flammability range of hydrogen-air mixture is stated to be from 4 % (LEL) to 74.2 % (UEL), however this is the case only at room temperature and the range widens with the increase of temperature. At 400°C it is already 1.4 % to 87.6 %, so in fact any mixture is combustible. There are further characteristics which make hydrogen so special: its gas-air mixture can be ignited with as little energy as 0,017 mJ, about 40-times less than required by gasoline-air mixture to ignite. For comparison, one cannot feel an electrostatic shock under 1 mJ. To exacerbate the risk, a perfectly burning mixture of hydrogen has a high temperature of 2318 K, but it is mostly invisible. Consequently, the common human senses that warn us a dangerous situation is developing – sight, smell, sound – are useless in dealing with a hydrogen leak. Only industrial quality instrument monitoring is suitable, but this is far too expensive and complex for mass consumer application.

The seriousness of this hydrogen ignition phenomenon is increased by the propagation velocity of a flame, which is about 6 times the speed of that of the frequently used hydrocarbons such as gasoline or propane. One should also be alert that hydrogen release or leak from a highly pressurized container creates static electricity which in turn can then self-ignite the releasing gas.

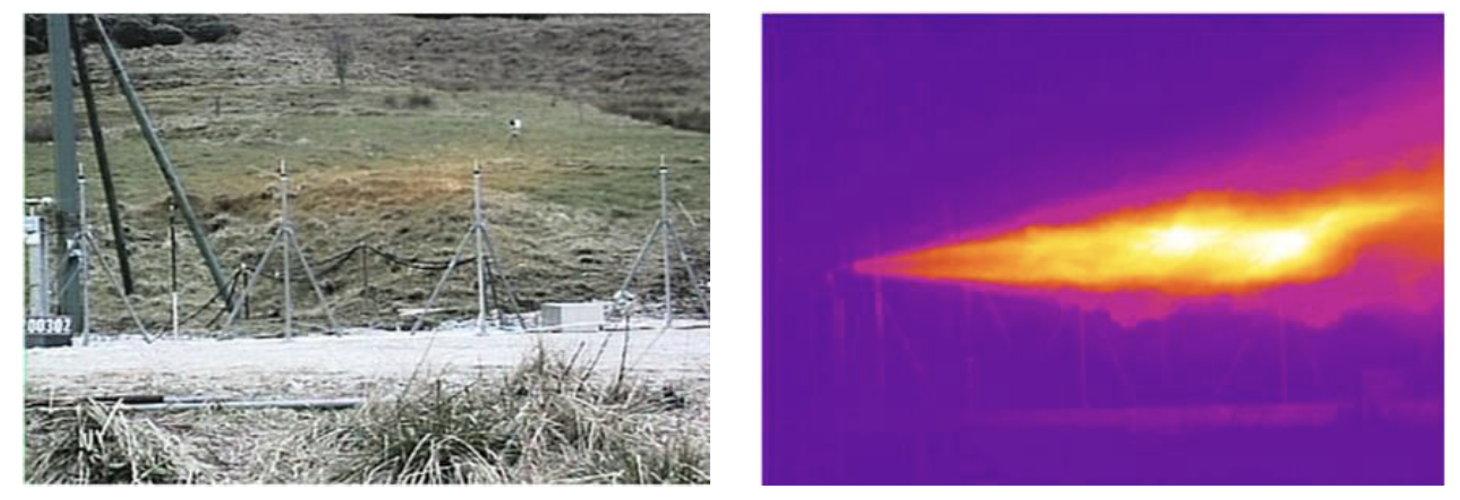

A release of unattended pressurized hydrogen excess into the air is accompanied by a jet flow and blast wave and a short lived high temperature “hemispherical cloud” which is like a fireball. “The speed of detonation wave depends on a composition of hydrogen-air mixture. In stoichiometric mixture it can be as high as 2000 m/s. The safety of hydrogen automotive applications and the related infrastructure, including garages, maintenance workshops, underground parking, and tunnels, is a main area of concern.” [HyTunnel-CS_D1.2 – Report on hydrogen hazards and risks in tunnels and similar confined spaces, 2019].

Policymakers and members of the public assume that these hydrogen (H2) molecule-related risks are well known and the large-scale automotive industry has found safe means to address them. However, when industry is under intense pressure to perform to a certain societally expected standard in a cost-competitive environment, it cannot keep everything under control or industry may find shortcuts that only appear to meet the objectives. If someone doubts this, they should familiarize themselves with the diesel emissions scandal, which shows how the systematic and self-confident “solutions” were the fault of most of the OEMs.

Compared to the diesel emissions scandal, it is consumer activity in hydrogen vehicle fueling that is the unaddressed challenge and hazard, rather than conformity to the existing regulations. Political forces are naïve to believe that, by decree or legislation, they can solve all those problems of working with hydrogen that have been detected within the last 50 years.

Let us review some risk statements, from the last few years declared by respected research centres:

- The Sandia National Laboratories: “Relatively large amounts of hydrogen often soluble in polymer materials; therefore, exposure to high-pressure hydrogen may cause damage (blistering or swelling) of the polymer materials. This is manifest in high-pressure applications due to depressurization of a system (or rapid temperature changes) as hydrogen expands in free volume and at interfaces within the polymers.”

- The HySafe project: “The reasons that cause the embrittlement of materials are still debated in the scientific community. Hydrogen embrittlement detection seems to be one of the most difficult aspects of the problem…. The main knowledge gaps on this matter are concentrated on the reasons that cause the embrittlement of materials…. Currently this phenomenon is not completely understood and hydrogen embrittlement detection, in particular, seems to be one of the most difficult aspects of the problem.”

- The HyCOMP project report noted about the safety calculation of the high-pressure fuel tanks: “As a result for the long-term operation, the increase in damage accumulation rate due to the elevation of the temperature could significantly affect the lifetime of the composites. It was calculated that the lifetime for the composites subjected to creep test at 70% of the average failure stress decreased from 2e+27 years to 0.2 year when the ambient temperature changed from the room temperature to 90 °C.” Despite reaching this conclusion, there was no responsive suggestion for a reduction of the Safety Factor for the different regulations which actually exist for the high-pressure hydrogen storage.

- In a tank rupture in a fire accident report by Lionel Perrette, Helmut K. Wiedemann concluded: “This remark underlines that tank fire protection and bus fire safety can not rely only on the performance of isolated protected tank systems.” – This can be explained; safety regulations are not sufficient to address the uncertainties of physical and chemical risks, particularly in moving vehicles that can encounter any number of unexpected circumstances that may lead to a crash or accident where the tank could rupture or the vehicle start on fire.

- Robert Zalosh in life simulating and analysing the vehicle tank incidents: “The results of these tests suggest that the danger zone associated with hydrogen cylinder rupture extends to a radius of roughly 100 m from the hydrogen vehicle.” This is about the length of a football field ».

- The European FP6 & FP7 supported HySafe project was daring enough to enforce the knowledge base of the hydrogen technology related incidents, but to remove barriers to deployment, stating: “…was to strengthen, integrate and focus fragmented research efforts to provide a basis that will allow removal of safety-related barriers to the implementation of hydrogen as an energy carrier. Synthesis, integration and harmonization of these efforts aimed at breaking new ground in the field of hydrogen safety and at contributing to the increase of public acceptability of hydrogen technology within Europe by providing a basis for communicating the risks associated with hydrogen. One of the means to achieve those objectives was the development and establishment of the Hydrogen Incident and Accident Database, HIAD”…HIAD is intended to become the up-to-date repository of any accidental event related to hydrogen technology.” – Well, this was an excellent initiative. BUT, the collected information database is NOT publicly available anymore for an unknown reason. Perhaps someone thought that it is better to hide this evidence from the public? As communicated by HIAD up to 2012; they had collected 250 hydrogen related accidental events with 835 people involved. The data base has been growing continuously since.

- The French Ministry’s ARIA Database recent publication [Hydrogen and transport: the risks should not be underestimated, 2020] makes it clear: “An analysis of 372 events involving hydrogen (produced or generated accidentally) in the ARIA database is a reminder that hydrogen remains a hazard even for proven industrial processes. For example, 73% of hydrogen incidents involved fires and/or explosions, 27% involved non-burning hydrogen leaks or hydrogen-induced stresses on materials without human consequences, 15% of fires and/or explosions involving hydrogen resulted in the death of at least one person and 43% resulted in injuries.” – while they stating it in an earlier publication – “With regard to the origin of accidents involving hydrogen, the analysis shows that in over 70 % of the cases “organisational and human factors”contribute to the deep-rooted causes of the accidents. Constant vigilance must be called for at all hierarchical levels in the facility – management, supervisory staff, technicians, subcontractors – while bearing in mind that there is a permanent risk of ignition in the presence of hydrogen.” [bold added]

- Even the big promoter of hydrogen in transport, the International Energy Agency’s working group (Hydrogen Implementing Agreement) wrote: “The lack of operating experience with hydrogen energy systems in consumer environments continues as a significant barrier to the widespread adoption of these systems and the development of the required infrastructure…. Although an understanding of hydrogen’s physical properties is well established, and there have been many experimental efforts attempted to fully characterize risks and hazards related to hydrogen, the actual risks and hazards are best be determined within the context of real systems and real operating experience. Likewise, previous experience with hydrogen has not been with systems that will interface with consumers, but in controlled environments using trained personnel.” – 2014.[bold added]

What has happened since 2014 when IEA wrote that H2 is not suitable for public application? For example: a tiny leakage which happened in a Norwegian fuel station in 2019, despite the fact that it was produced and operated by one of the most experienced companies that deals with hydrogen globally, and that the station was not more than 2.5 years old. The leakage happened because of bolts around an O-ring that were not properly torqued. The blast wave that followed sent parts of the station which were found in a 200 m radius, just to mention one figure.

As it must be clear from the words above that hydrogen – in consumer hands – constitutes a risk for society. While a very expensive part of the hydrogen system in the vehicle, i.e. the tank, has only a lifetime of 15 years as limited by the respective regulation, the vehicle fleet in Europe even in the wealthier EU member states is drastically ageing, while the poorer countries are reporting around or sometimes over 15 years as the average age of the current car stock. The European emission regulations have been forcing a rapid acceleration of the vehicle price, while the latest Euro 6d has effectively eliminated most of the small and mid-category entry priced new vehicles from the market. As a consequence, the ageing of the vehicle stock is speeding-up within the EU, and so it is in their used vehicle markets in the Balkans and in Africa. To replace a hydrogen tank after 15 years costs more than an average used vehicle nowadays, which means vehicle owners will not readily to replace them. As it is stated, and as de facto accidents have demonstrated, if a tank is overused it destroys everything in its surrounding.

If you still believe in hydrogen as safe fuel for future vehicles, just read my complete paper: Rising safety hazard related to hydrogen on-road applications as H2 leaves the controlled laboratory environment [link to full article].